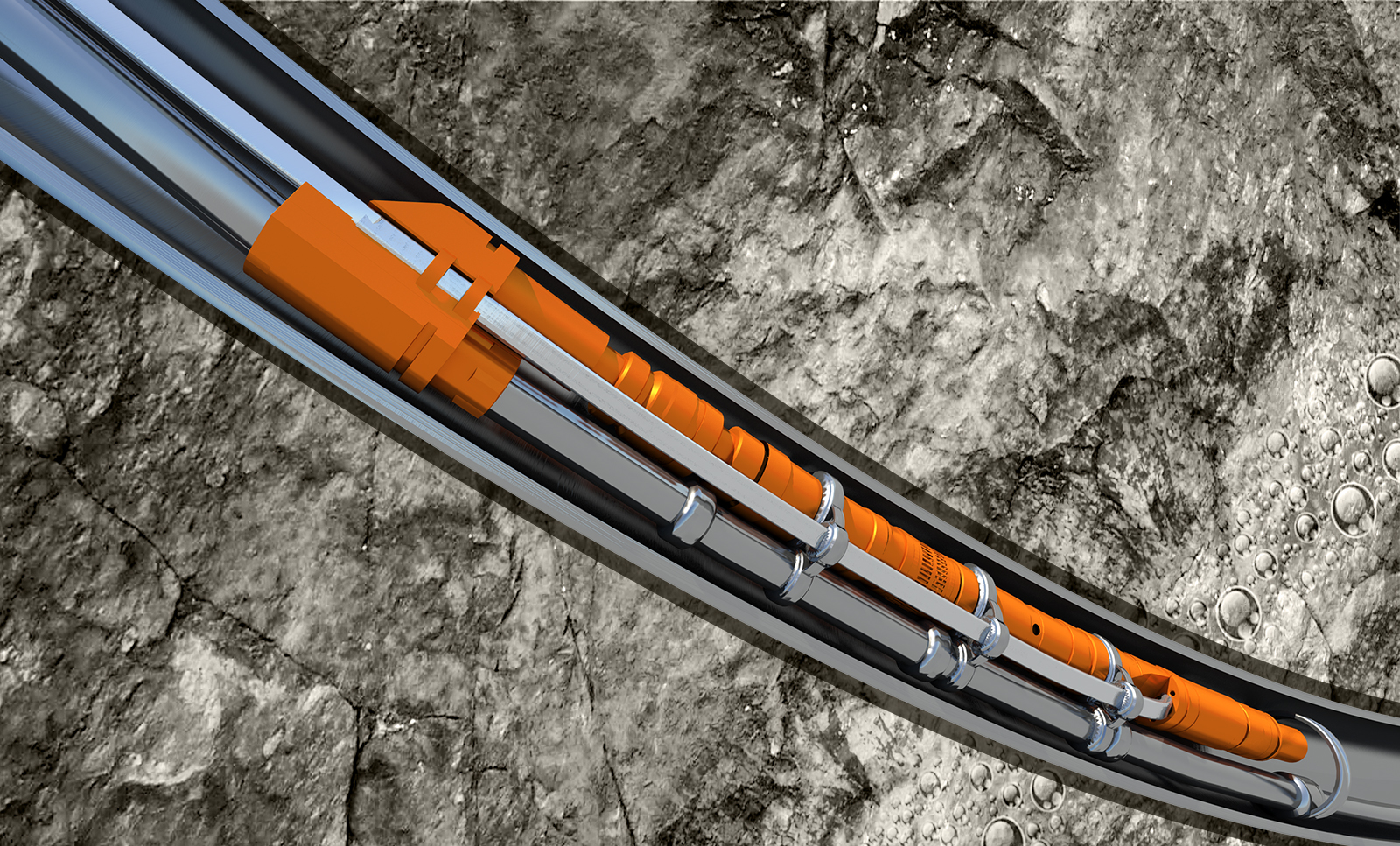

Y-TOOL ESP BYPASS SYSTEM

ESP bypass systems, commonly called Y-tools, are used to gain access to the wellbore below an electrical submersible pumping (ESP) system without having to retrieve it. This enables stimulation, production logging, testing, and interventions on wireline or coiled tubing without having to deploy a workover rig and pull the completion.

BENEFITS

The bypass conduit enables easy access to the wellbore below the ESP using coiled tubing or wireline

The ESP remains in place while logging runs are conducted and during coiled tubing interventions

A second ESP can be run through the bypass conduit to enable additional production from the well

applications

- Production logging and intervention operations in ESP-produced wells

- Horizontal and vertical wellbores

- Dual-depth ESP production

capabilities

- Can be run in wellbores as small as 5.75 in. (146 mm)

- Protects the ESP during natural flow and bullheading operations

features

- The bypass conduit enables access to the wellbore below the Y-tool while the ESP remains in place

- The design enables production logging to be conducted below the intake while the ESP is operational

Y-tool bypass systems are run on production tubing and consist of two conduits. One conduit is offset and houses the ESP, keeping it firmly positioned in the wellbore. The other conduit provides a path for access to the wellbore below the system.

Common applications include conducting production logging, reservoir analysis, and well tests below the ESP. Coiled tubing can be used to push logging tools deeper into laterals, to engage and actuate flow control devices, to set plugs for water shutoff operations, and other coiled tubing intervention jobs. The bypass conduit can also be used to run an additional ESP below the Y-tool system to add additional production from nearer the production zone.

TECHNICAL CHARACTERISTICS

|

ESP size (RU) |

ESP size |

Casing size |

Capacity |

Logging tool max OD |

Coiled tubing max OD |

|

3 |

3.19 in. |

5.75 in. |

1,761 bbl/d |

1.18 in. |

1 in. |

|

81 mm |

146 mm |

280 m3/d |

30 mm |

25.4 mm |

|

|

3 |

3.19 in. |

6.625 in. |

1,761 bbl/d |

1.85 in. |

1.5 in. |

|

81 mm |

168 mm |

280 m3/d |

47 mm |

38 mm |

|

|

4 |

3.38 in. |

6.625 in. |

1,258 bbl/d |

1.23 in. |

1 in. |

|

86 mm |

168 mm |

200 m3/d |

32 mm |

25.4 mm |

|

|

3 |

3.19 in. |

7 in. |

1,761 bbl/d |

2.05 in. |

1.5 in. |

|

81 mm |

178 mm |

280 m3/d |

52 mm |

38 mm |

|

|

4 |

3.38 in. |

7 in. |

1,258 bbl/d |

1.57 in. |

1 in. |

|

86 mm |

178 mm |

200 m3/d |

40 mm |

25.4 mm |

|

|

5 |

3.62 in. |

7 in. |

3,145 bbl/d |

1.42 in. |

1 in. |

|

92 mm |

178 mm |

500 m3/d |

36 mm |

25.4 mm |

|

|

5A |

4.06 in. |

7 in. |

5,661 bbl/d |

1.23 in. |

1 in. |

|

103 mm |

178 mm |

900 m3/d |

32 mm |

25.4 mm |

|

|

7A |

5.35 in. |

9.625 in. |

10,064 bbl/d |

2.24 in. |

1.75 in. |

|

136 mm |

245 mm |

1600 m3/d |

57 mm |

44.5 mm |

Y-Tool bypass system case studies

.jpg)