HISTORY OF NOVOMET

NOVOMET » Company Pages for Novomet » History of Novomet

History of Novomet

-

1991The history of Novomet began in 1991 when the company founders began using powder metallurgy to manufacture pump stages—a first in the oil and gas industry.

-

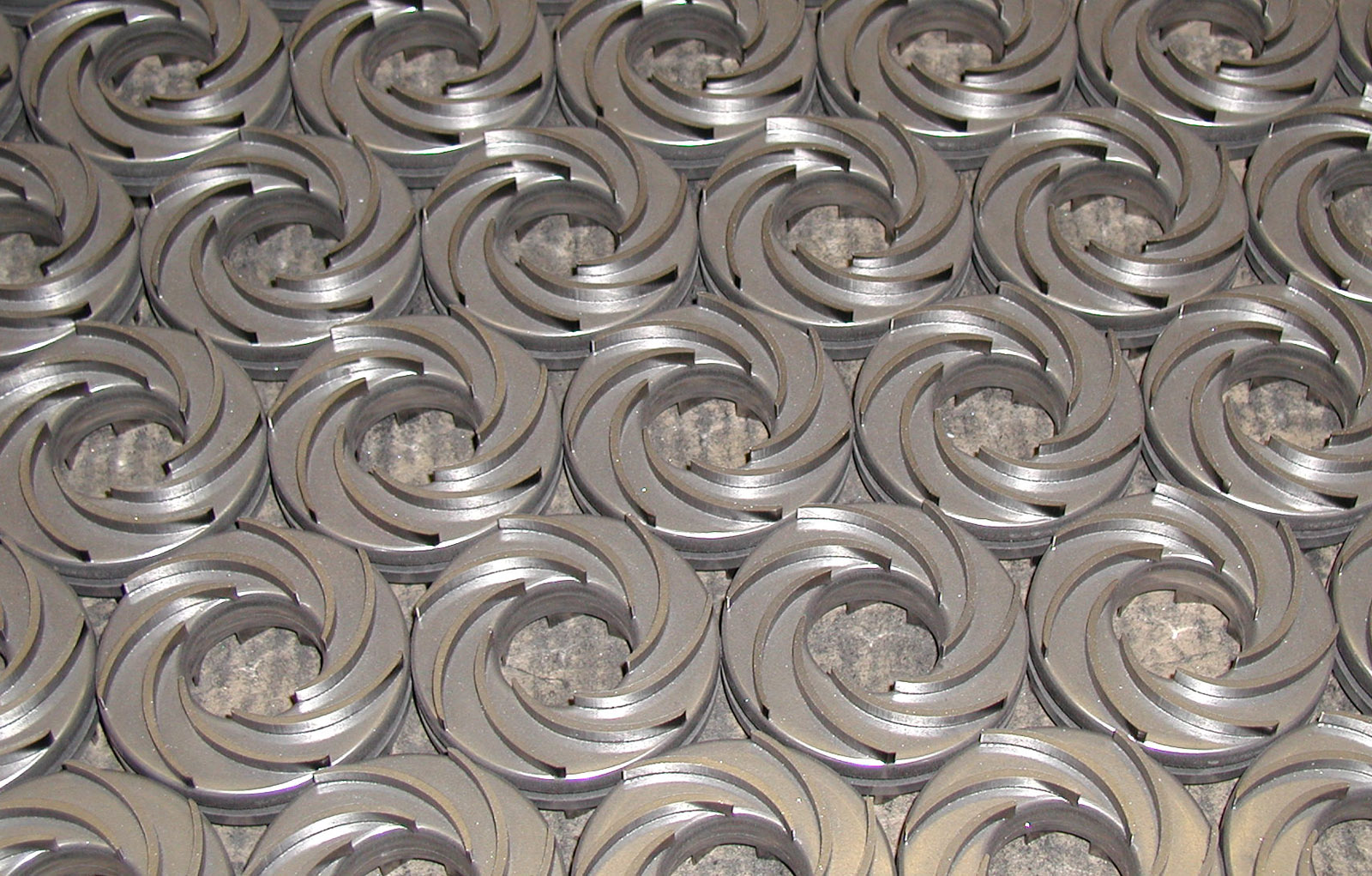

1992Novomet started out supplying powder metallurgy pump stages to electrical submersible pumping (ESP) system manufacturers. Powder metallurgy involves pressing components from a mixture of metallic ores. It has proven to be a far more precise method of manufacturing than sand casting, enabling Novomet pump stages to deliver superior performance and longevity in extreme downhole environments.

-

1998In 1998, we released our own line of centrifugal-vortex pumps. They not only improved runlife in challenging downhole conditions, but also improved efficiency.

-

2002In 2002, we began development of various components—pumps, motors, protectors, gas separators, check valves, and additional supporting wellsite equipment—that enabled us to release a new line of complete ESPs.

In 2003, we established a service division, with a network of service bases located close to customers. This expansion enabled us to deliver best-in-class service and support alongside our best-in-class products. -

2012We led the move to design and develop a new ESP motor that would be more powerful, smaller, and far more efficient than the old-style asynchronous induction motors. Little did we know when we launched our first line of ESP permanent magnet motors (PMMs) that the Novomet name would become synonymous with PMM technology in the oil industry. We also began manufacturing our own variable speed surface drives at this time to control our high-RPM permanent magnet motors.

-

2017As we continued to offer smaller sizes of permanent magnet motors and pumps, we realized we had a great opportunity to invent an entirely new type of ESP system. With some redesign, we developed the world’s first cable-deployed ESP. With successful installations going back to 2017, the Colibri cable-deployed rigless ESP remains the only truly rigless downhole pumping system. It can be deployed, controlled, and retrieved under live-well conditions without having to use a drilling or workover rig.

-

2019As binary cycle geothermal powerplants grew in popularity, so did the need for downhole pumps that could stand up to the hot, high-flow, high-salt conditions of geothermal wells. Novomet engineers applied decades of knowledge they had gained in designing ESPs for similar harsh conditions to the geothermal industry. With a redesigned motor-lead-extension, enlarged protectors, and the adoption of high-temperature-tolerant materials, Novomet launched its first line of geothermal pumps. Today our Geyser geothermal submersible pumping (GSP) systems are the most widely used geothermal ESP in Turkey. Powered by highly efficient PMMs, our Geyser systems deliver the required high flowrates at extreme temperatures while also reducing the electricity required to pump geothermal fluid.

-

2021ESP installations require downhole cable… and lots of it. Some systems can be installed as deep as 5000 m (16,400 ft). Having reliable cable is critical for successfully operating an ESP and supporting long runlife. To better control cable supply, we opened our own manufacturing facility for producing high-temperature ESP cable. This helps us better control costs and reduce lead times by matching ESP and cable orders at the time of manufacture.

-

TODAYOur research and development capabilities are unsurpassed in the industry and yield immediate performance improvements for our customers. We have thrived by leading the industry in technological innovation and are always excited to solve new problems for our customers.

We have undergone continued global expansion over the past decade. We now employ more than 5,500 people and maintain a network of service centers around the world supporting customers in every major oil market.