TEST BENCHES

We test, upgrade, and repair equipment at our operations bases around the world. We use standard testing for all our systems before sending them to the field and can customize testing as needed for customers.

We also supply the following test benches and equipment along with training to customers who need to conduct their own testing:

- Storage equipment (racks, shelves, etc.)

- Electrical submersible pumping (ESP) system cleaning stations

- Manual and automated assembly/disassembly benches for downhole and surface equipment

- Quality control stations for testing repaired components

Open Motor Testing

The open motor test bench is used to flush and fill motors with oil and to run a series of acceptance tests before the motor can be shipped to the field. Basic equipment includes a stand (workbench), a cabinet containing high-voltage switches and converters, a control and measuring workstation, software and hardware, and induction controller, and a transformer.

Test list:

- Measuring insulation resistance of stator windings in cold and hot condition

- Determining polarization index

- Measuring phase resistance of stator windings with direct current

- Conducting a short circuit experiment (determining the current short circuit - the initial starting current, the active power short circuit, the power factor short circuit, the magnitude of the torque at short circuit)

- Determining engine acceleration voltage

- Conducting run-in for 2 hours (time may vary) at the rated voltage for the ESP (test voltage, phase-by-phase currents, current asymmetry, total idle losses, power factor, stator temperature, motor vibration)

- Dividing total idle losses into steel and mechanical losses

- Testing electric strength of interturn insulation of the stator winding

- Determining rotor run time

- Checking insulation resistance of stator windings with installed Downhole Sensor System (voltage 500 V)

Loaded Motor Testing

The loaded motor test bench is used for both acceptance and maintenance tests. Basic equipment includes a test bed, a load induction motor and regulator, a torque measuring system, a step-up transformer, a cabinet containing high-voltage switches and converters, a control and measuring workstation, software and hardware, a low-voltage equipment cabinet, and a remote control.

Test list:

- Measuring insulation resistance of stator windings in cold and hot condition

- Determining polarization index

- Measuring phase resistance of stator windings with direct current

- Conducting a short circuit test (determination of the short-circuit current - the starting current, the short-circuit active power, the short-circuit power factor, the short-circuit torque at short-circuit, the loss in winding during the short-circuit test)

- Determining motor acceleration voltage

- Conducting run-in for 2 hours (time may vary) at the rated voltage of the ESP (test voltage, open-circuit currents in phase, current asymmetry, total open-circuit loss, power factor, stator temperature, motor vibration)

- Dividing total idle losses into steel and mechanical losses

- Testing electrical strength of interturn insulation of the stator winding

- Determining the run-down time of the rotor

- Checking insulation resistance of stator windings with installed Downhole Sensor System (voltage 500 V)

- Determining rated torque Mnom (N * m) and static load characteristics for the motor

- Calculating the natural mechanical characteristic M = f (n) at a reduced voltage, where M (N * m) is the moment on the shaft, n (r / min) is the speed of rotation with the definition of starting Mpusk, minimum Mmin and maximum Mmax moments

Protector Testing

The protector test bench is used to fill our ESP protectors with oil and to conduct run-in testing. Basic equipment includes a metal frame; a power module; hydraulic, pneumatic, and power moving systems; a pneumatic cylinder; a rigid retainer; an electric hoist; a control panel; and a pallet.

Test list:

- Conducting a run-in test with right and left rotation

- Performing hydroprotection test at axial pressure with right and left rotation

Pump Section Testing

The pump section test bench is used for parametric, classification, and acceptance testing before ESP pump sections are sent into the field. It uses automation to provide full remote control over all testing inputs and enables quick configuration adjustments.

Test list and advantages of automated testing:

- Eliminates arbitrary interpretation of test results

- Measures flow, shaft power and speed, inlet and outlet pressure, vibration, and temperature and density of the pumped-over fluid

- Controls stand valves, frequency converter, and booster pump operation mode

- Enables testing of pump sections from other manufacturers with the ability to change rotation direction and frequency

Current Leak Testing

The current leak test bench measures the amperage lost by the ESP cable during normal operation. It is designed to test cable up to 11,400 ft (3500 m) long with a 0.054 in.2 (35 mm2) core section using amperage up to 30 kV. Lost current is measured with an accuracy of 0.001μA with a resolution of up to 10-9

Basic equipment includes a mobile storage cabinet, a multimeter, a high-voltage source (0-30 kV, up to 2.5 mA), a high-voltage switch with contactors (up to 35 kV), shunt measuring, a measuring control unit, and a computer with an integrated relay board, monitor, and printer. Integrated software automates testing, collects and stores sensor data, and provides digital and/or printed visual outputs.

Horizontal ESP Testing

The horizontal ESP test bench measures flow, power, pressure, vibration, and efficiency of ESP systems to certify them beforebeing sent into the field for installation. An automated registration system displays test data and results in both tabular and graphical formats. It also processes and stores data for further analysis and enables quick configuration adjustments.

Test list and advantages of automated testing:

- Eliminates arbitrary interpretation of test results

- Measures flow, shaft power and speed, inlet and outlet pressure, and stage efficiency

- Enables testing of pump stages from other manufacturers with the ability to change rotation direction and frequency

Motor Assembly

The motor assembly test bench is used to assemble both the induction and permanent magnet motors that drive ESP systems. Basic equipment includes:

- A metal test bed

- An assembly toolkit

Other Equipment

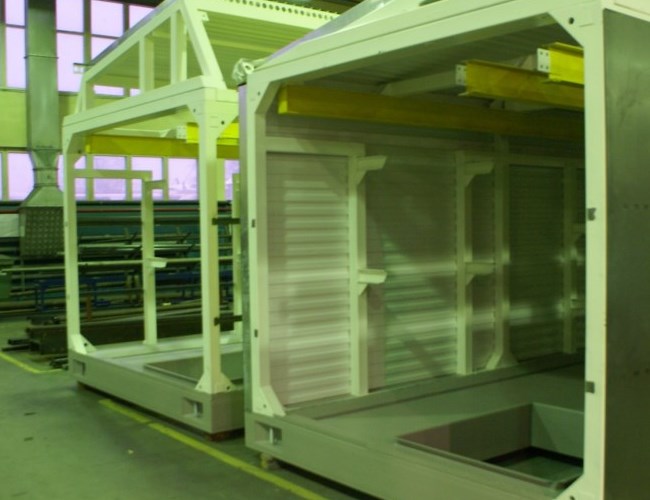

Typical non-standard equipment includes block boxes and block-box modules that house and protect various pumping systems, equipment, and even people. They can be mobile or permanent and are used for multiple applications, including:

- Booster pumping stations

- Fluid transfer stations

- Surface pump injection well stations

- Sewage treatment plants

- Workshops, warehouses, driers, etc.