MONITOR AND CONTROL ESPs FROM ANYWHERE

NOVOMET » Products and Services » Artificial Lift » Artificial Lift Software » Remote Monitoring

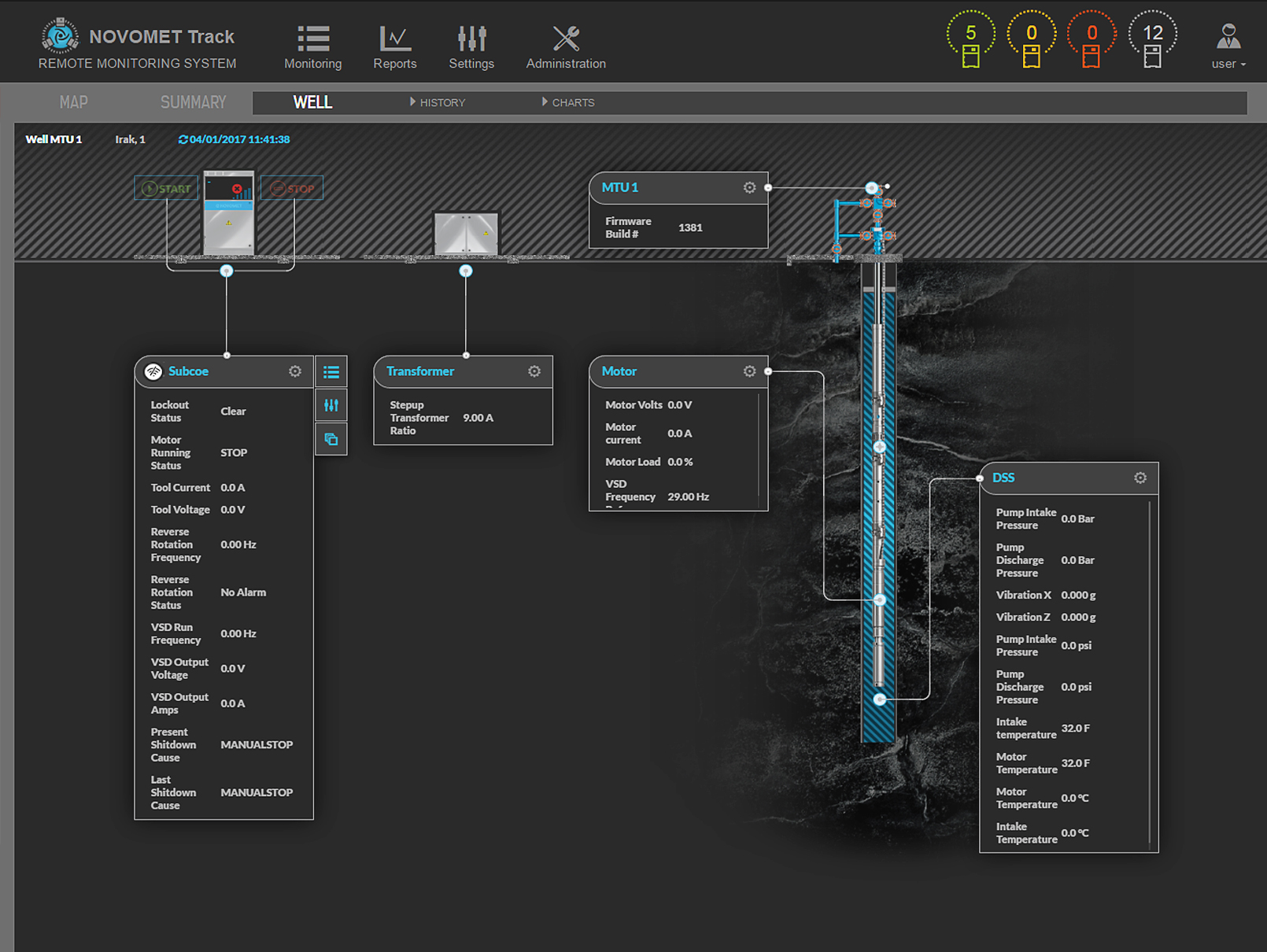

NOVOMET TRACK REMOTE MONITORING AND CONTROL SYSTEM

The Novomet Track remote monitoring and control system delivers real-time access to downhole sensor and surface data through a secure cloud-based connection. It offers full remote control of the variable speed drive (VSD), enabling you to see and immediately respond to production changes.

BENEFITS

Get real-time access to well data

—A secure, cloud-based connection delivers real-time data from downhole sensors and the VSD

Reduce ESP cycling and increase uptime

—Remote control lets you alter pump speeds to avoid gas lock, overheating, and shutdowns

Reduce operating and production costs

—Remote access and control eliminate service trips, reduce downtime, and lower costs

applications

- Wells produced by ESPs

- Conventional, unconventional, onshore, and offshore wells

- Remote and high-value wells

capabilities

- Remotely monitor production, troubleshoot problems, and take corrective action from anywhere

- View, download, and analyze VSD and downhole data logs

features

- Intuitive interface enables easy monitoring and control of the VSD and ESP

- Novomet servers and secure cloud storage provide real-time access to data

- Data preparation capabilities include VSD logs and data reporting to identify curves and trends

About the Novomet Track remote monitoring and control system

The Track system uses hardware and software to provide full remote monitoring and control capabilities for VSDs, and by extension ESPs. Encrypted secure socket layer (SSL) technology protects your valuable data while enabling you to access it across the internet.

The Novomet Track system is made up of the following software and hardware:

- VSD monitoring and control software coupled with a high-speed, wireless general packet radio service (GPRS) modem

- Secure cloud data storage linked to Novomet servers

- A personal computer with internet access

Advantages

- Delivers real-time access to production and VSD data

- Enables faster troubleshooting and reaction times

- Reduces downtime

- Eliminates need for service calls in many instances

- Reduces service costs and HSE risk

- Reduces overall production costs

Capability details

Data collection and transfer

- Collection and transfer of data from downhole sensors via modem or satellite

- Access to data from anywhere across the internet using a secure SSL connection

- Varying permission levels for personnel groups

Monitoring

- VSD control and real-time monitoring of VSD and ESP parameters

- Automatic alarms and warnings

Control

- Activating, deactivating, and adjusting operating modes and protections

- Motor startup, shutdown, and RPMs

Data preparation and reporting

- Collecting and storing VSD data logs

- Adjusting data output filters

- Generating reports, building curves, and identifying trends

Need more info?

Contact us for more information about using intelligent well technology to monitor and control your ESPs