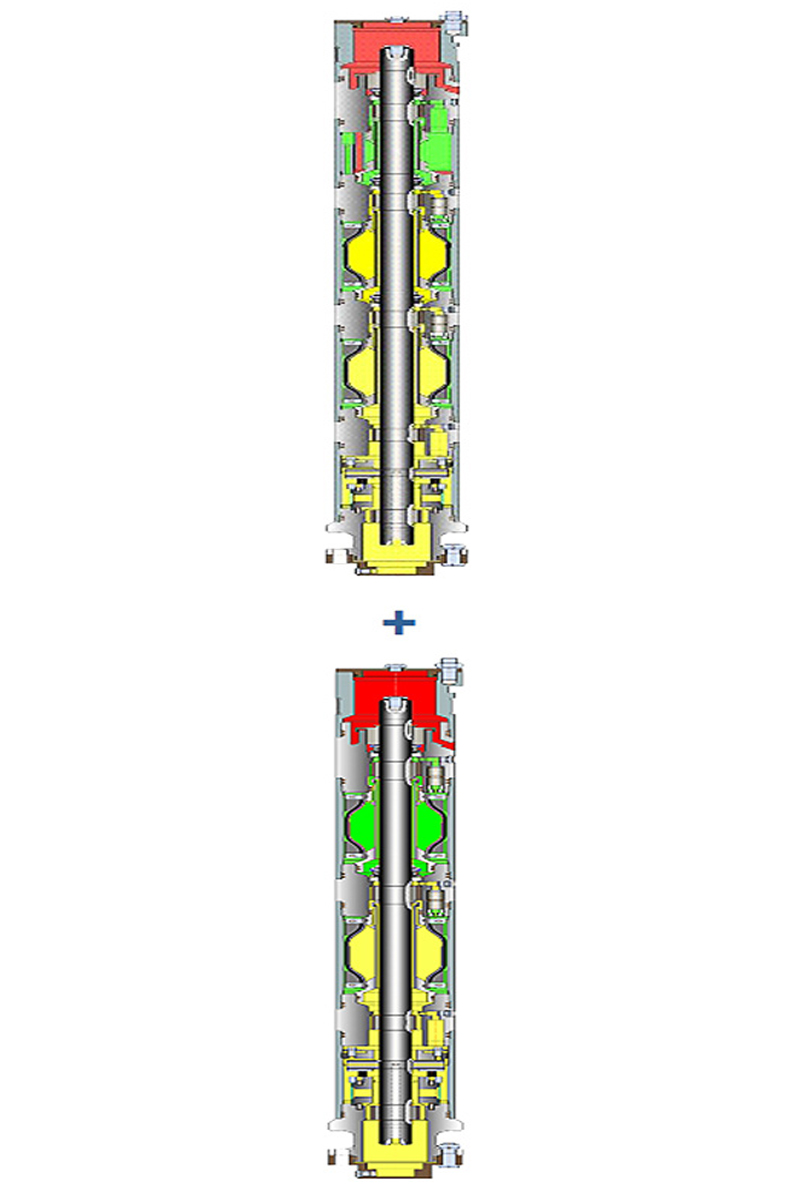

TANDEM ESP PROTECTORS

Connecting two or more modular ESP protectors in a series enhances motor protection. Tandem ESP protectors are used in harsh environments, in production programs that require high pump rates, and in wells where production is periodic with lots of stops and starts.

BENEFITS

Using tandem protectors reduces the impact of harsh conditions to extend ESP service life

Greater protection enables you to use more powerful pumps and motors in your ESP design

Tandem bearings reinforce the shaft and increase the axial load limit

applications

- Conventional and unconventional wells using an ESP

- Vertical, directional, and horizontal wellbores

- Harsh downhole conditions and high pump rates

- Wells that produce only periodically

capabilities

- Available in 272 (69 mm), 319 (81 mm), 338 (86 mm), 362 (92 mm), 406 (103 mm), 449 (114), 535 (136 mm), and 677 (172 mm) series

- Designed to perform with high-power motors and high-rate pumps

features

- Tandem configuration enables you to protect high-power motors and high-rate pumps and easily replace or upgrade equipment if needed

- Doubling the protection extends ESP runlife in harsh conditions

- Two axial bearings work in tandem to increase axial load limits

TECHNICAL CHARACTERISTICS

|

Outer Diameter |

Shaft Diameter |

Thrust bearing load limit |

Maximum Motor Power |

Oil volume |

Max Oil volume of motor |

Length |

Weight |

|

2.72 in. |

0.50 in. |

4500 lb (@60Hz) |

TBA |

6 liters |

18 liters |

TBA |

TBA |

|

69 mm |

14 mm |

1700 kg (@50Hz) |

|||||

|

3.19 in. |

0.79 in. |

4500 lb (@60Hz) |

289 hp (@60Hz) |

8 liters |

18 liters |

7.56 ft |

221 lb |

|

81 mm |

20 mm |

1700 kg (@50Hz) |

180 kw (@50Hz) |

2.31 m |

100 kg |

||

|

3.62 in. |

0.98 in. |

5292 lb (@60Hz) |

320 hp (@60Hz) |

15 liters |

23 liters |

14.98 ft |

331 lb |

|

92 mm |

25 mm |

2000 kg (@50Hz) |

200 kw (@50Hz) |

4.57 m |

150 kg |

||

|

4.06 in. |

0.98 in. |

7144 lb (@60Hz) |

579 hp (@60Hz) |

18 liters |

31 liters |

14.98 ft |

397 lb |

|

103 mm |

25 mm |

2700 kg (@50Hz) |

360 kw (@50Hz) |

4.57 m |

180 kg |

||

|

4.49 in. |

1.38 in. |

8203 lb (@60Hz) |

720 hp (@60Hz) |

20 liters |

40 liters |

8.04 ft |

595 lb |

|

114 mm |

35 mm |

3100 kg (@50Hz) |

450 kw (@50Hz) |

2.45 m |

270 kg |

||

|

5.35 in. |

1.50 in. |

11907 lb (@60Hz) |

1126 hp (@60Hz) |

40 liters |

80 liters |

18.19 ft |

772 lb |

|

136 mm |

38 mm |

4500 kg (@50Hz) |

700 kw (@50Hz) |

5.55 m |

350 kg |

More about our tandem ESP protectors

Tandem ESP protector configuration uses two or more modular protectors in series to add increasing levels of ESP motor protection.

Schemes for connecting the protectors include:

- Labyrinth, sequential diaphragm, parallel diaphragm, sequential diaphragm, parallel diaphragm, sequential labyrinth

- Labyrinth, sequential diaphragm, parallel diaphragm, sequential diaphragm, parallel diaphragm

- Aperture, parallel aperture, sequential aperture, parallel aperture

Using two diaphragms instead of one enables you to add an additional sliding bearing, increasing shaft rigidity. Two axial bearings work in tandem, increasing axial load limits the shaft can bare. If one of the supports fails, the load is absorbed by the second support.