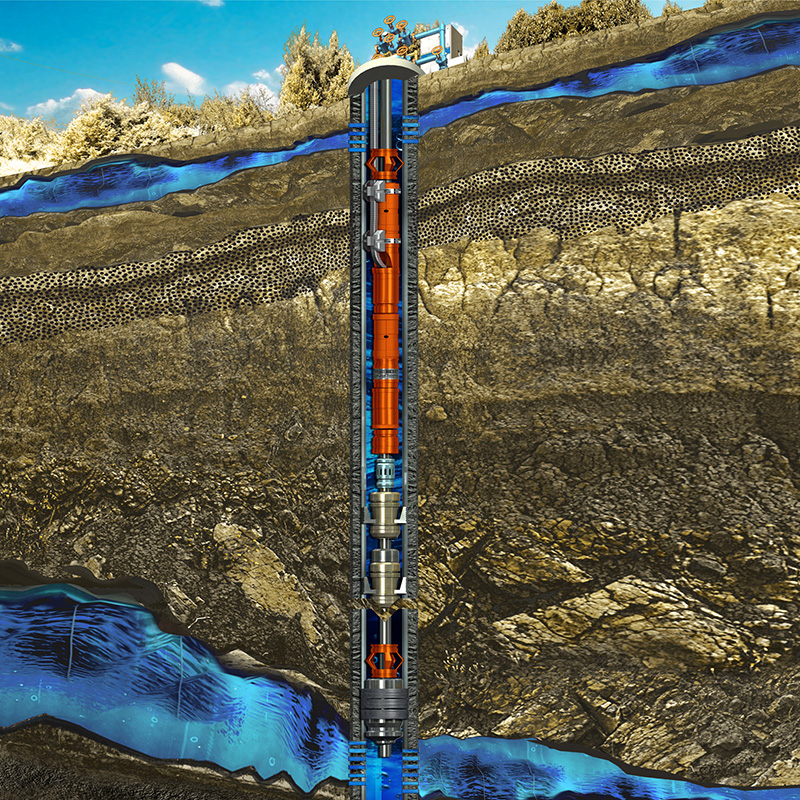

Water Injection Pumps

Water injection pumps are used to force water, wastewater, waste field oil, and brine deep underground into porous formations. Injection can be used as an enhanced oil recovery (EOR) method in reservoirs where pressures are dropping. With EOR operations, fluid is injected in one well to build reservoir pressure and push hydrocarbons toward an offset production well.

Injection pumps are also used in disposal wells. Somewhere around 3 barrels of water are produced for every barrel of oil harvested from the earth. That leaves a lot of wastewater that must be dealt with. Many operators turn to disposal wells because they remain the most economical way to offload produced water.

BENEFITS

Efficient ESP design reduces power consumption, lowering injection and disposal costs

When a well has reached the end of its economic life, reuse the VSD to control the injection pump

Increase or decrease injection rates to manage and optimize recovery in the production well

applications

- Offset injection wells used in enhanced oil recovery

- Disposal wells

capabilities

- Flowrates from 95 – 39,600 BPD (15 – 6,300 m3/d)

- Inlet pressures up to 5,000 psi and outlet pressures up to 3,000 psi

features

- Rugged construction extends runlife

- Efficient motors and pump stages reduce power costs

TECHNICAL CHARACTERISTICS

Standard

|

Size (RU) |

Size |

Capacity |

Head |

Efficiency rate |

|

4 |

3.38 in. |

226-1,510 bbl/d (@60Hz) |

11,483 ft |

39-61% |

|

86 mm |

30-200 m3/d (@50Hz) |

3500 m |

||

|

5 |

3.62 in. |

113-4,151 bbl/d (@60Hz) |

11,483 ft |

31-67% |

|

92 mm |

15-550 m3/d (@50Hz) |

3500 m |

||

|

5A |

4.06 in. |

189-5,283 bbl/d (@60Hz) |

11,483 ft |

33-65% |

|

103 mm |

25-700 m3/d (@50Hz) |

3500 m |

||

|

6 |

4.49 in. |

6,038-9,435 bbl/d (@60Hz) |

11,483 ft |

62-66% |

|

114 mm |

800-1250 m3/d (@50Hz) |

3500 m |

||

|

6A |

4.84 in. |

981-1,887 bbl/d (@60Hz) |

11,483 ft |

53-61% |

|

123 mm |

130-250 m3/d (@50Hz) |

3500 m |

||

|

8 |

6.77 in. |

3,774-30,191 bbl/d (@60Hz) |

8,202 ft |

63-66% |

|

172 mm |

500-4000 m3/d (@50Hz) |

2500 m |

||

|

9 |

7.40 in. |

37,739-47,551 bbl/d (@60Hz) |

6,562 ft |

70-72% |

|

188 mm |

5000-6300 m3/d (@50Hz) |

2000 m |

||

|

10 |

9.00 in |

60,382-75,478 bbl/d (@60Hz) |

4,921 ft |

73-79% |

|

229 mm |

8000-10000 m3/d (@50Hz) |

1500 m |

Power Save

|

Size (RU) |

Size |

Capacity |

Head |

Efficiency rate |

|

2A |

2.72 in. |

151-755 bbl/d (@60Hz) |

11,483 ft |

45-57% |

|

69 mm |

20-100 m3/d (@50Hz) |

3500 m |

||

|

3 |

3.19 in. |

189-2,415 bbl/d (@60Hz) |

11,483 ft |

40-70% |

|

81 mm |

25-320 m3/d (@50Hz) |

3500 m |

||

|

5 |

3.62 in. |

251-3,019 bbl/d (@60Hz) |

11,483 ft |

46-66% |

|

92 mm |

20-400 m3/d (@50Hz) |

3500 m |

||

|

5A |

4.06 in. |

755-3,774 bbl/d (@60Hz) |

11,483 ft |

67-71% |

|

103 mm |

100-500 m3/d (@50Hz) |

3500 m |

||

|

7A |

5.35 in. |

2264-16,982 bbl/d (@60Hz) |

9,843 ft |

67-76% |

|

136 mm |

300-2250 m3/d (@50Hz) |

3000 m |

||

|

8 |

6.77 in. |

12,076-18,869 bbl/d (@60Hz) |

8,202 ft |

74-76% |

|

172 mm |

1600-2500 m3/d (@50Hz) |

2500 m |

Inverted ESP water injection pump benefits:

- Reduce power costs on injection and disposal wells

- Reuse the VSD in wells being converted from ESP production to injection/disposal

- Control frequency and injection rates in EOR operations to optimize production

- Dispose of wastewater in the most common and economical manner

- Choose from a wide range of flow rates

Water injection pump case study