DOWNHOLE ESP SENSORS

Downhole ESP sensors measure and transmit information from the electrical submersible pumping (ESP) system to the surface where it can be monitored and analyzed to optimize system performance and extend ESP runlife.

BENEFITS

Change motor speed to accommodate dynamic downhole conditions and optimize production

Adjust ESP speed to avoid gas locking and to align with production rates as they decline over time

Use temperature, pressure, and flowrate readings to better identify and predict reserves

applications

- ESP health monitoring

- Pump-side flowrate measurements

- Data source for protection algorithms, ESP control, and intelligent production systems

capabilities

- Standard configuration measures insulation resistance, pump intake pressure and temperature, motor winding temperature, and vibration

- Advanced configuration also includes pressure readings taken at the pump outlet

- Extended configuration adds pump vibration and discharge pressure, temperature, and flowrate readings

features

- Highly accurate sensors deliver reliable, high-resolution data

- An expanded set of sensors delivers pump-side flowrates and data

Our downhole ESP sensors can be run with all Novomet ESP systems, regardless of whether they are powered by an inversion motor or a permanent magnet motor. They gather and send measurements to the surface where the data can be used to calculate and hone protector algorithms, optimize ESP performance, control intelligent production systems, and update reserve calculations.

TECHNICAL CHARACTERISTICS

Standard Configuration

|

Measured parameter |

Measurement range |

Resolution |

Precision |

|

Insulation resistance |

0 – 1000 kiloohm |

1 kiloohm |

2.50% |

|

1001 – 9999 kiloohm |

10% |

||

|

Pump intake pressure |

0 – 40 MPa |

0,001 MPa |

0.50% |

|

Pump intake temperature |

0 – 150°C |

0.1°C |

1% |

|

32 – 302°F |

0.1°F |

1% |

|

|

Motor winding temperature |

0 – 220°C |

0.1°C |

1.50% |

|

32 – 428°F |

0.1°F |

1.50% |

|

|

Motor vibration |

0 – 30 mm/s2 |

0.1 mm/s2 |

5% |

|

0 – 0.0465 in./s2 |

0.0002 in./s2 |

|

Extended Configuration

|

Discharge pressure |

0 – 40 MPa |

0.001 MPa |

0.50% |

|

Discharge temperature |

0 – 150°C |

0.1°C |

1% |

|

32 – 302°F |

0.1°F |

1% |

|

|

Discharge flowrate |

8 – 40 m3/d |

0.1 m3/d |

3% |

|

50 – 251 bbl/d |

|||

|

30 – 200 m3/d |

|||

|

188 – 1256 bbl/d |

|||

|

100 – 500 m3/d |

|||

|

628 – 3140 bbl/d |

|||

|

200 – 1200 m3/d |

|||

|

1256 – 7536 bbl/d |

|||

|

Pump vibration |

0 – 30 mm/s2 |

0.1 mm/s2 |

5% |

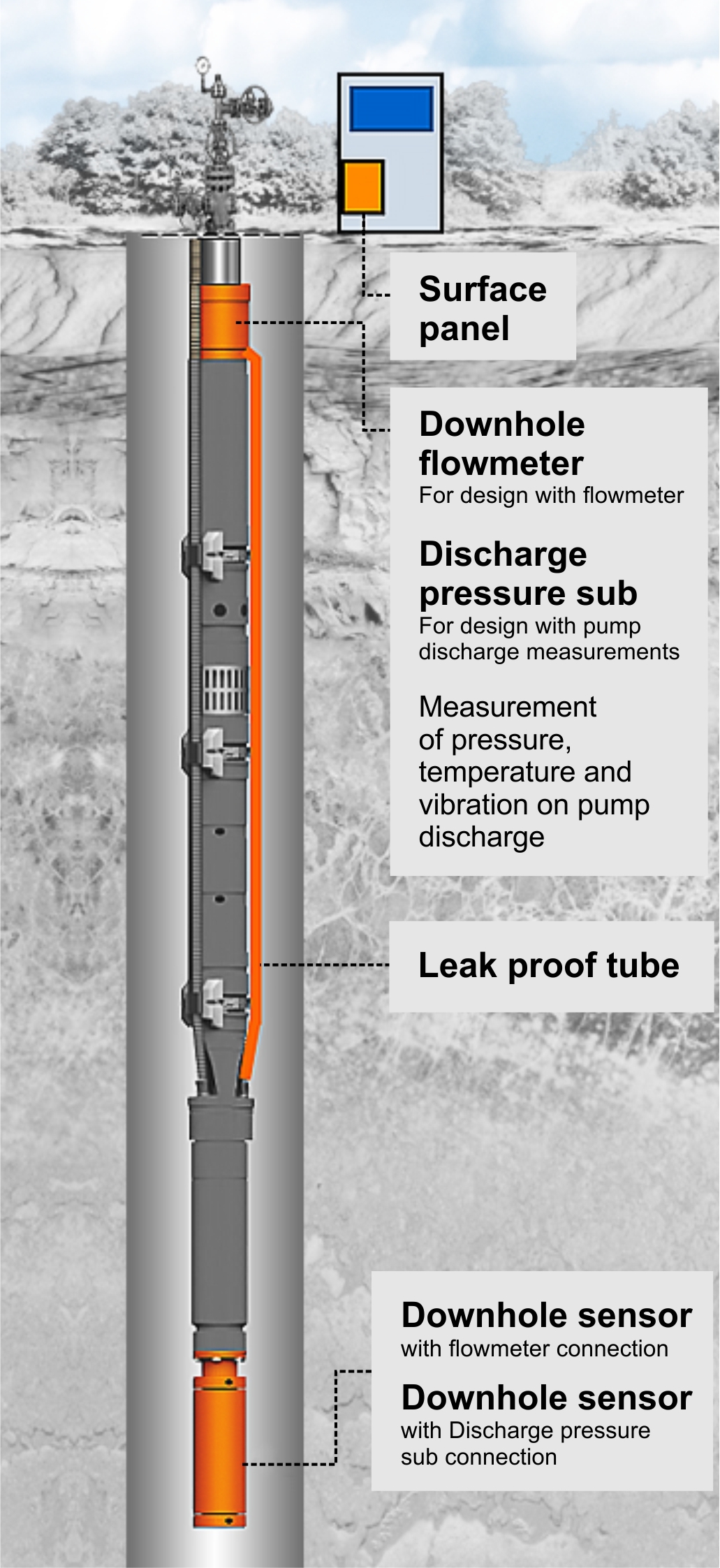

The standard configuration takes measurements at the pump intake. It measures fluid temperature and pressure, motor temperature and vibration, and the total combined insulation resistance of the motor, cable, and transformer. As an option, you can also choose a stainless-steel tube add-on that measures pressure at the pump outlet.

The extended configuration also takes readings at the pump outlet and includes a flow meter. It measures all the parameters included in the standard configuration and adds readings for pressure and temperature at the pump outlet, pump vibration, and flowrate of reservoir fluid as it exits the pump.